Sensors, Connectors, RFID & Vision

Distributed I/O

Distributed I/O

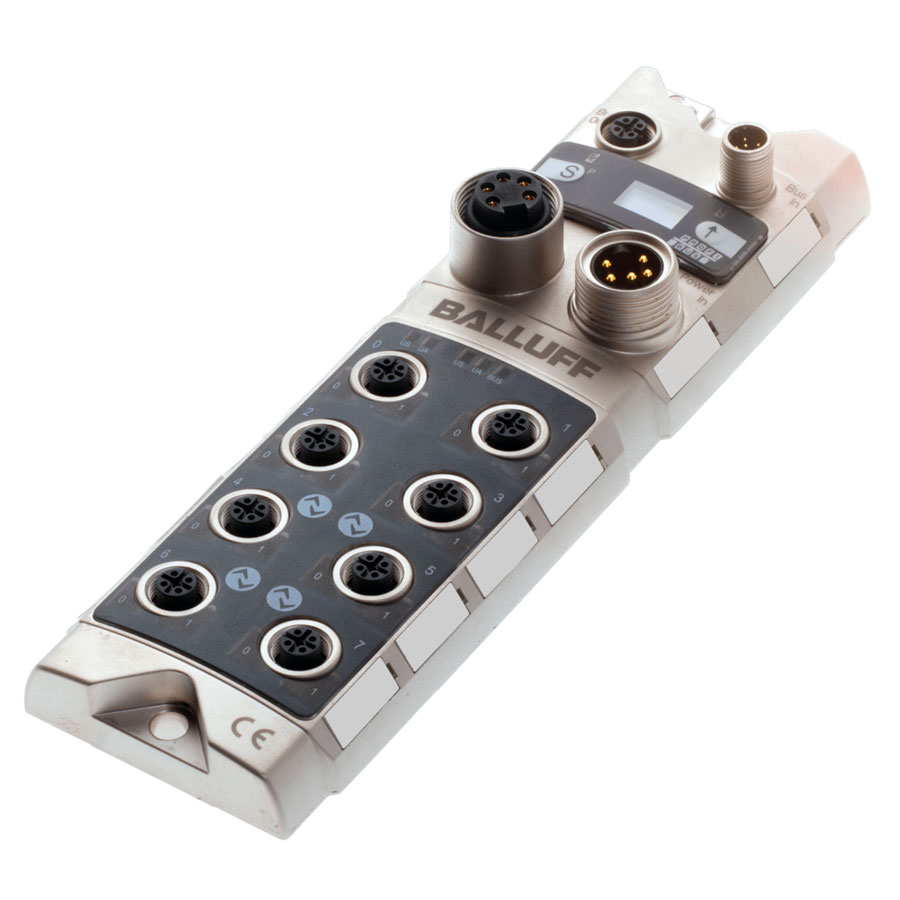

Balluff IO-Link is a powerful standard (IEC 61131-9) for setting up intelligent solutions for industrial automation. The digital interface is a fieldbus-neutral, point-to-point distributed I/O connection. It is the first globally standardized distributed IO that communicates from the controller down to the lowest automation level and integrates sensors as well as actuators at the fieldbus level. Control concepts using IO-Link provide simple and universal solutions for a high-performance, consistent network.

Intelligently combining industrial networks with the IO-Link communication standard is the ideal solution for ever faster, more flexible, more efficient and more adaptable production. It provides a powerful infrastructure for reliably managing the growing volume of data, transporting data through the entire manufacturing process and achieving seamless communication from the intelligent sensor up to the internet.

The IO-Link communication interface offers tangible benefits: quick and cost-saving installation, continuous diagnostics and quick sensor replacement configured from a central location, improving flexibility and automation efficiency. The uniform standard interface can be quickly integrated into the fieldbus world, even complex devices. Without expensive, shielded cabling, the digital communication ensures noise immunity. Analog signals are digitized with no conversion losses.

IO-Link enables quick and error-free exchange of sensors and shortens the time needed to start system operation. Downtime can be significantly reduced, since the IO-Link master or the controller automatically writes the parameters of a replaced IO-Link sensor onto the new sensor. IO-Link sensors can be positioned in the machine directly at the location of operation because the sensor’s accessibility no longer plays a role. Process monitoring, configuration and error analysis of the IO-Link sensors take place in the controller.

IO-Link can be used universally

The interface communicates from the controller down to the lowest automation level and can be connected with nearly any fieldbus system. Only a standard cable and a standardized port with M5, M8 or M12 connectors are needed. Furthermore, using IO-Link, sensors can be built in directly at the location of operation, where they are optimally placed in terms of technical aspects of the process.

IO-Link is an intelligent enabler of technology

The standard enables the exchange of process data, service data and events. In doing so, IO-Link offers the possibility of saving parameter data directly in the IO-Link master. That gives the advantage of allowing the saved information to be automatically taken over during a device exchange. Thus, parameter data for a new, identical replacement device can be used easily, saving time and reducing errors.

IO-Link is simple

IO-Link distributed I/O makes the installation and the exchange of new devices easier and guarantees error-free data transfer. Each device has an IODD (IO Device Description), where information on the manufacturer, the article number or the function is saved and is clearly readable. The clear classification enables easy parameterization, error analysis and process oversight, all of which is also possible from mobile end devices, regardless of location. The accessibility of the sensors no longer plays a role thanks to IO-Link. The relevant information is saved and can be called up at a central location in the controller.

Balluff has an extensive range of IO-Link products from IO-Link ready sensors to master, slave and I/O hubs. IO-Link is not a fieldbus; rather it’s a connection technology for three-wire sensors and digital I/O. With a maximum of 240 sensors on one 8-port master I/O block, IO-Link simplifies wiring, reducing costs 15%-60%. Master block fieldbus communications support all major networks including Ethernet/IP, DeviceNet, PROFInet, PROFIbus, EtherCAT, CC-Link and CC-Link IE Field.

For more information on Distributed I/O from Balluff, as well as how Power Motion can help, please contact us. We have locations in St. Louis, Kansas City and Little Rock, providing distributor and automation solutions services for Missouri, Kansas, Arkansas, Nebraska, Southern Illinois, Southern and Western Iowa, Northern Louisiana, Eastern Oklahoma and Northeast Texas. Not all products available in all areas.