Indicators, Lighting & Alarms

Pick-to-Light Systems

Pick-to-Light Systems

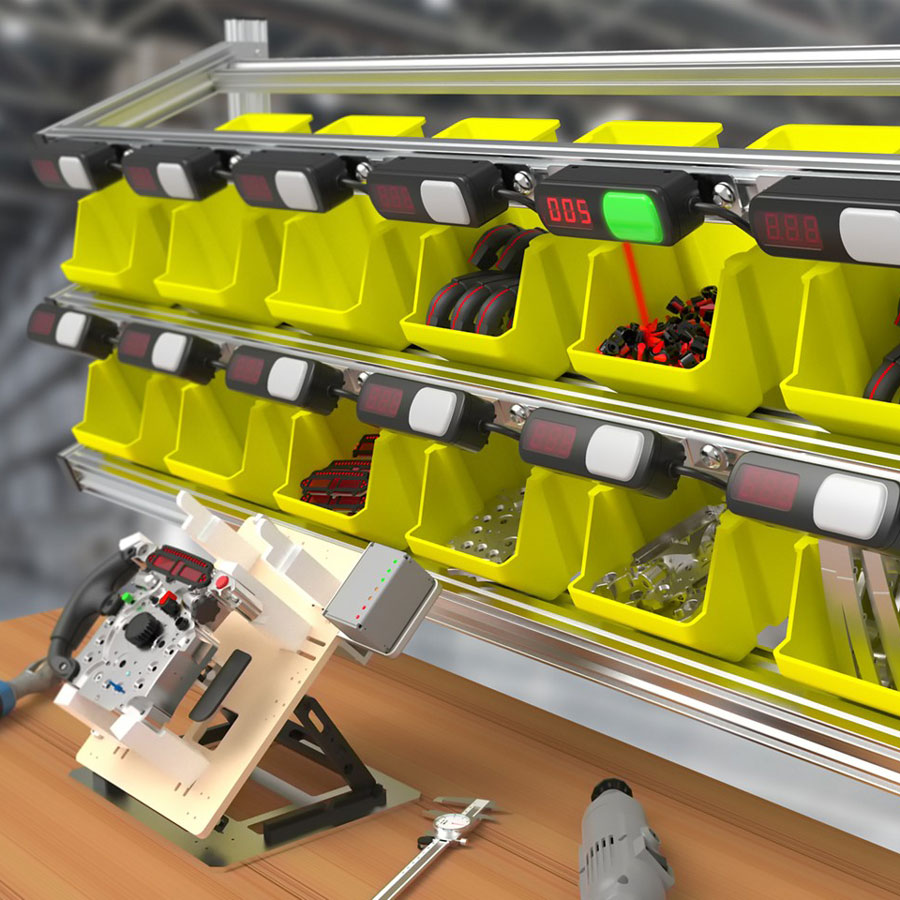

Banner Engineering’s pick-to-light systems provide light-guided assembly for lean manufacturing initiatives, boosting product quality and reducing cost. By lowering the risk of human error in production and assembly processes, these systems are an ideal solution for poka-yoke (error-proofing). They visually guide operators to pick the correct parts, in the right quantities and the proper sequence. This reduces errors and defects and increases productivity by eliminating a common source of wasted time like checking and re-checking instructions.

Light-Directed Picking Systems

Pick-to-light, also known as light-directed or light-guided picking, refers to the use of colored LED indicators to guide assemblers and operators to the correct part or product location. These solutions can also be used to indicate the number of parts to pick and proper pick order. They make manual picking processes faster and more accurate in a wide variety of applications including assembly, kitting and order fulfillment.

Manual assembly often requires multiple parts and steps to complete, and at each step, there is a risk of human error. An incorrect part may be picked out of a part bin, or parts may be put together in the wrong order. However, accuracy is critical to ensure a high-quality final product, and manufacturers need assemblies completed quickly to maximize throughput. The challenge is to increase assembly speeds while maintaining quality.

To improve efficiency and accuracy in assembly applications, it is essential for the assembler to be able to quickly and easily identify the next pick location. A pick-to-light solution identifies the correct bin for the assembler to pick from, detects that the pick has been made and then notifies the assembler of the location of the next pick. Flexibility gives users the choice to align with their preferred operating procedure, and the technology is adaptable to a wide array of manufacturing processes.

Applications:

- Multiproduct Assembly Stations

- Mobile Assembly Stations

- Indication of Takt Time for Assembly

- Light-Guided Kit Building

- Part Pick Verification

- Error-Proofing Assembly Applications

- Order Fulfillment – Wide Shelf

- Long Bin Pick-to-Light

- Incorrect Pick Signal

- Stocking and Replenishment

Pick-to-Light Solutions Kit

Banner’s new solutions kit for improved productivity in picking systems is an easy-to-use way to reduce error during the assembly process. It comes with a pre-programmed DXM700 and HMI with touch screen for quick and cost-effective pick-to-light system setup and integration. The kit harnesses the power of all models of PICK-IQ devices, is simple to mount and install, and solves more applications with flexible pick functionality.

This kit is an integrated solution that consists of an enclosure, a DXM controller, HMI, and direct connections for PTL110 devices and power. The integrated device and power decrease installation costs, improve picking sequences and ensure flexible pick functionality. The combination of pick-to-light devices and the solutions kit help manufacturers reduce the risk of error in the assembly process, boosting product quality and reducing labor cost.

For more information on Pick-to-Light Systems from Banner Engineering, as well as how Power Motion can help, please contact us. We have locations in St. Louis, Kansas City and Little Rock, providing distributor and automation solutions services for Missouri, Kansas, Arkansas, Nebraska, Southern Illinois, Southern and Western Iowa, Northern Louisiana, Eastern Oklahoma and Northeast Texas. Not all products available in all areas.