Sensors, Connectors, RFID & Vision

Vision Tools

Vision Tools

Cognex’s customizable vision tools are used to inspect, match patterns and identify codes. Cognex pioneered some of the earliest commercial applications for machine vision with their vision and barcode reading technology. Today, companies around the world rely on these technology tools to guide assembly, automate inspection, and speed production and distribution. Cognex’s patented algorithms produce solutions for diverse applications in virtually all manufacturing and logistics industry sectors.

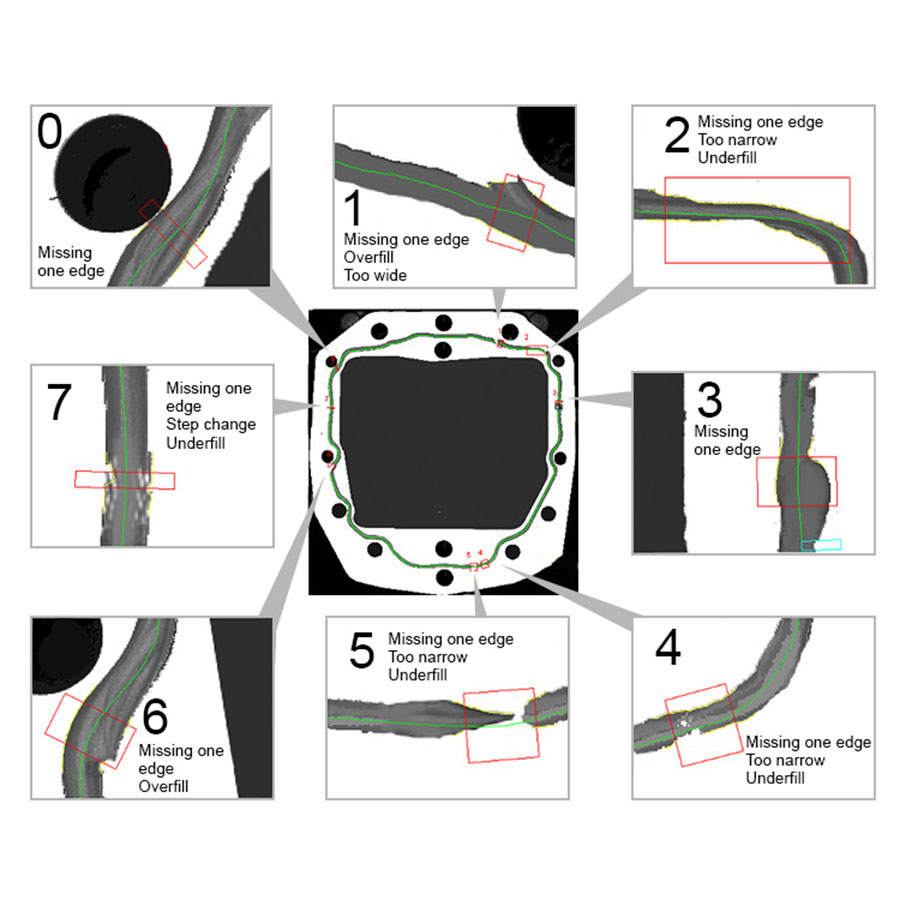

Bead Inspection Vision Tools

Automated glue bead inspection is critical in the automotive and electronics industries. BeadInspect is an all-in-one bead width and position inspection tool used to detect anomalies. BeadInspect offers a robust inspection of the bead line – even if bead size, shape, and appearance change over time. This is important when inspecting a freshly applied, wet or shiny RTV bead, or when the beads vary in location from part to part. BeadInspect enables users to:

- Easily train the bead path, with just a few clicks, using the PolyLine function

- Find defects in beads that change or differ in shape

- Determine width based on defects and gaps

- Remove noise for increased robustness

Edge Detection Tools

Edge detection is essential for inspection, as well as measurement and gauging applications. Cognex offers a large variety of tools to measure the width of objects, locate edges of features and measure the spacing of pairs despite changes in part orientation and lighting. Cognex offers a variety of edge tools, including Caliper and LineMax, for manufacturers’ edge/line-finding needs.

Edge Inspection Tools

Cognex’s powerful edge inspection tools find gaps, defects along edges, and other area-based and surface flaws. These tools robustly measure min/max deviations to find edge/area-based defects on products, as well as surface flaws and print defects. Easily configured for straight, circular or non-uniform edges, edge inspection tools classify defects by total area, length or depth. InspectEdge and Flexible Flaw Detection tools offer ultimate flexibility to find gaps along a line path and inspect shapes for boundary defects.

Color Vision Tools

Cognex offers advanced color tools for applications including part sortation, color recognition and matching, inspection and assembly verification, including:

- SearchMax: Finds colored patterns allowing translation, rotation, scale and skew

- Color Extractor and Segmentation: Provides simple color definition for complex color scenes, as well as high-speed color extraction for food and packaging applications

- Color Match: Enables high-speed identification and sorting of colored parts

Pattern Matching Tools

Pattern-matching is a manufacturer’s most powerful tool for part location and inspection, but pattern matching is extremely challenging because many variables can alter the way an object appears to a vision system. Cognex PatMax and its companion tools are the industry’s gold standard for part and feature location using pattern-matching. Cognex pattern-matching tools help users locate patterns regardless of rotation, scale or lighting conditions reliably and accurately with patented geometric pattern-matching technology.

Histogram Image Processing

The Cognex Histogram tool computes histograms and histogram statistics for acquired images. A histogram is a one-dimensional function of pixel values that represents the distribution of pixel values in a window, typically characterized by the presence of peaks, or modes, representing the pixel values found in the dominant window features. The effects of noise from various sources – for example, spatial quantization error, uneven printing, irregular lighting or electrical noise – cause these peaks to spread out. Machine vision applications rely on the Histogram tool to determine pixel count, contrast, and brightness.

Measurement Vision Tools

Measurement tools help establish reliable feature-based parameters and thresholds. Measurement tools output quantitative information, either in pixels or real-world units. This information may be used as pass/fail criteria, data for another tool or data to send to an external device. Cognex measurement tools include:

- Distance: Measures the distance between features, not just edges. References two edge tools.

- Angle: Determines the angle between two edges. References two edge tools.

- Circle radius: Measures the distance from the center of a circle to its edge. Creates an arc finder and returns the radius measurement.

- Calibration: Calibrates camera pixels to real-world units.

Identification Tools

Cognex advanced identification technologies ensure high read rates of 1D and 2D symbols, as well as read and verify difficult characters, in the most challenging manufacturing and logistics applications.

For more information on Vision Tools from Cognex, as well as how Power Motion can help, please contact us. We have locations in St. Louis, Kansas City and Little Rock, providing distributor and automation solutions services for Missouri, Kansas, Arkansas, Nebraska, Southern Illinois, Southern and Western Iowa, Northern Louisiana, Eastern Oklahoma and Northeast Texas. Not all products available in all areas.