“Working with Power Motion is always a pleasure. The team is highly experienced, well versed in product knowledge and continuously gives a great response time. With regards to our current project utilizing Mitsubishi J4 Servo Drives with an older control system, they have been invaluable. Their experience and assistance with product startup has been excellent.”

—Adam Nelson (Owner, reACTIV Laser Systems)

The Situation

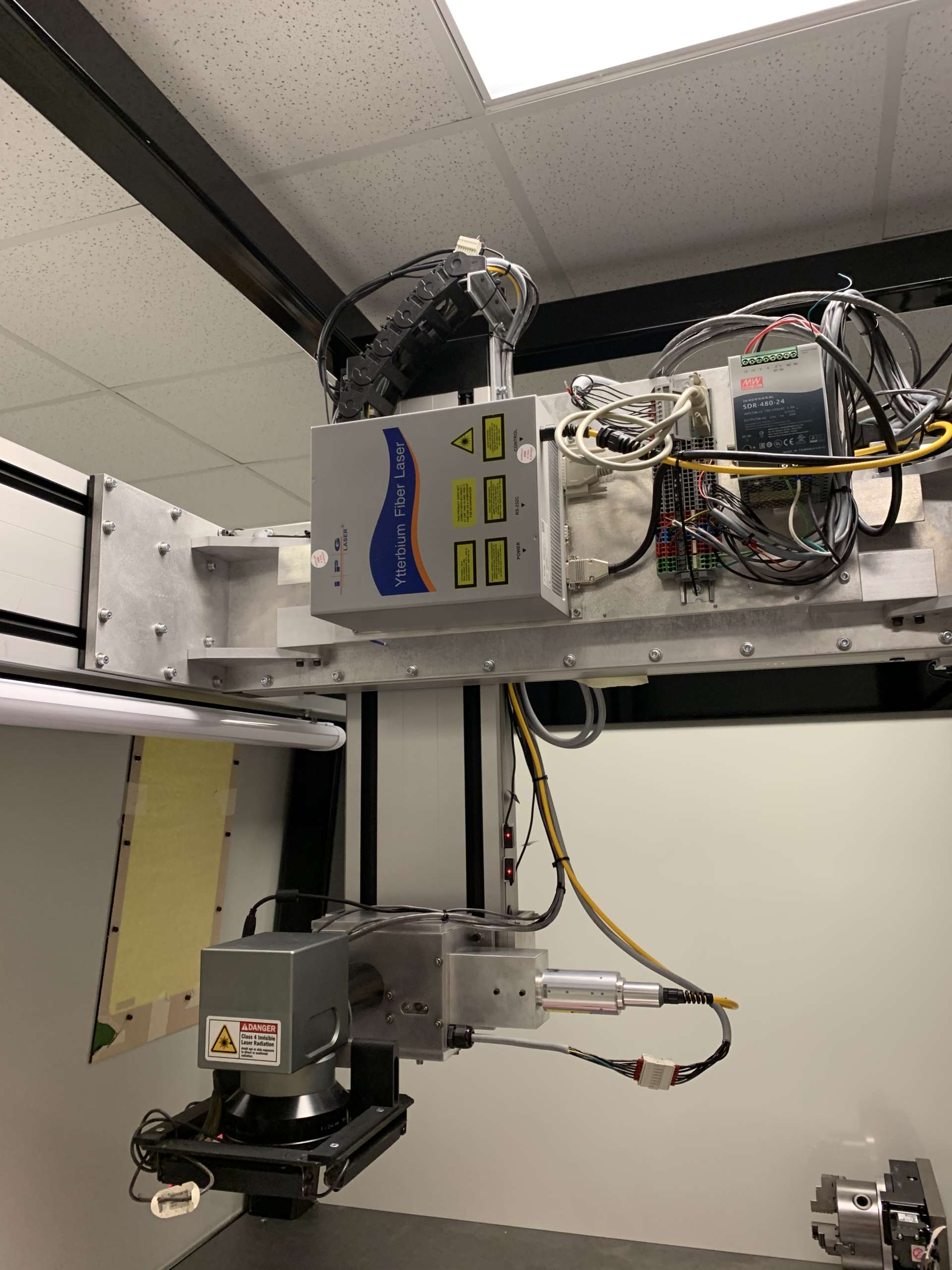

A 20-year-old laser system that still has a lot of life left in it. An obsolete servo that was discontinued in 2013 and no longer supported by the manufacturer. A desire to upgrade the servo drives and motors without having to replace the entire control system. This was the challenge reACTIV Laser Systems brought to Power Motion. reACTIV supplies a wide range of industrial laser systems for manufacturing. They wanted to replace a Mitsubishi Electric MR-J2 servo with an MR-J4 servo. They also wanted to maintain the machine’s existing motion control scheme so they could shift data from the old system to the new one.

The Solution

No one in the world makes backward compatibility and forward migration as easy as Mitsubishi Electric. Mitsubishi developed a solution for running MR-J4-A Servos in MR-J2 CL compatibility mode so the new servo could communicate with the old PC-based controller. They also created an instruction manual to support migration of legacy systems in the field. Using this migration solution, Power Motion quickly and cost-effectively upgraded the laser without having to replace the entire control system, which would have required more hardware and significantly more time.

The Value

The MR-J4 servo is providing reACTIV with world-class quality and industry-leading performance, including:

- 16 times the encoder resolution of the MR-J2 Series

- Four times the processing power for greater throughput

- Three times faster motion network performance

The MR-J4 servo also offers:

- Automatic adjustment of servo gains simply by turning it on

- Advanced vibration suppression control for shorter settling times

- Greater operator control and the ability to increase the system’s

resolution with a higher pulse rate

reACTIV valued the fundamental product and engineering knowledge Power Motion brought to the project, the quick and helpful customer service and response the team provided, and also the fact that the project was successfully completed under budget.